Converting ammonia production to a low-emission process is one of the major challenges in the fight against climate change. Ammonia, one of the most widely produced chemicals worldwide, is essential for the fertiliser industry and thus for the production of plant-based food. However, it is expensive to produce and causes high emissions.

A research team from Forschungszentrum Jülich, the Technical University of Munich and Linde Engineering has conducted a study simulating what a reactor would need to look like to produce ammonia cost-effectively and in an environmentally friendly way, i.e. based on renewable energies. The results have now been published in the International Journal of Hydrogen Energy. International Journal of Hydrogen Energy veröffentlicht.

Ammonia as a climate factor

According to the British Royal Society, global ammonia production generates around 500 million tonnes of CO₂ annually – equivalent to Germany’s annual CO₂ emissions and around 1.8 per cent of global emissions. The main reason for this is that conventional ammonia synthesis requires hydrogen, which has so far been obtained almost exclusively from fossil natural gas – a process that releases large amounts of CO₂.

Green ammonia offers a climate-friendly alternative here: the hydrogen (H₂) required is not obtained from natural gas, but from water via electrolysis. This is split into oxygen (O₂) and hydrogen using electricity from renewable energies. The hydrogen produced then reacts with nitrogen (N₂) from the air in the Haber-Bosch process to form ammonia (NH₃).

The challenge: rapid load changes

The problem is that electricity from wind and solar energy is not continuously available. This means that electrolysis does not supply the same amount of hydrogen at all times, causing fluctuations in the supply to the plant. In order for an ammonia plant to respond flexibly to these fluctuations, it must be able to ramp up and down its production, i.e. it must be load-flexible.

However, conventional plants are designed for continuous, uniform operation. Rapid load changes lead to severe pressure fluctuations inside the reactors and pipelines. This places high mechanical stress on the components. To withstand this permanently, the equipment would have to be built with thicker walls and more robust materials – which would significantly increase costs and make the design much more complex.

This is precisely where the new study comes in: it shows how these pressure fluctuations can be reduced with intelligent control – and thus also the requirements for the mechanical stability of the plants.

‘For green ammonia to contribute to the fight against climate change, the costs must be competitive,’ says Prof. Andreas Peschel, Director at the Institute for Sustainable Hydrogen Economy at Forschungszentrum Jülich and co-author of the study.

According to the study, this can be achieved with a novel pressure control system in what is known as an ammonia loop. This production step ensures that unused reaction gases such as hydrogen and nitrogen are fed back into the process. According to the team’s simulations, the flexible control of this loop allows load changes to be implemented at high speed and with low pressure fluctuations.

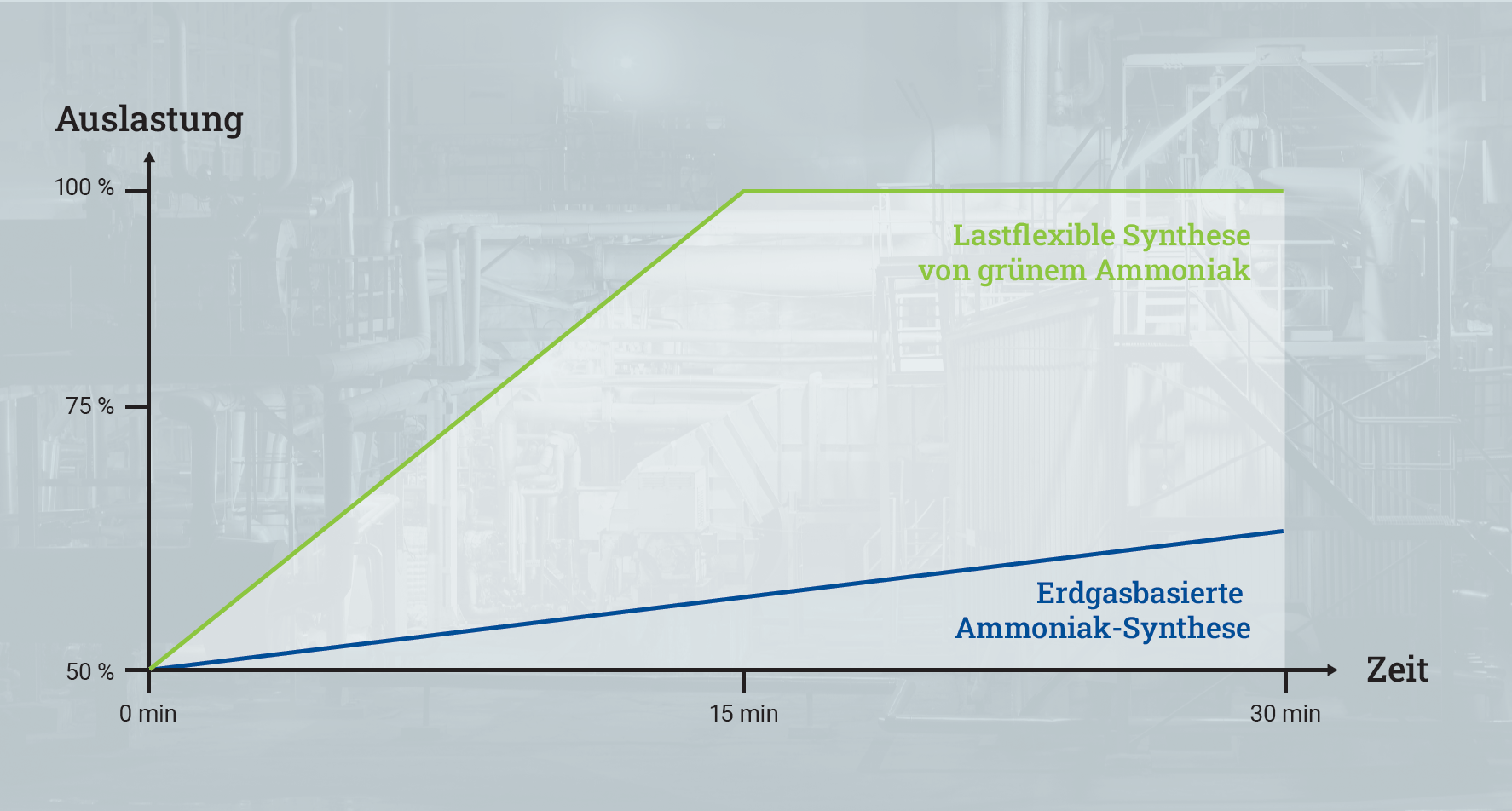

Production output can be changed by three percent within one minute – a speed that is not possible with today’s natural gas-based plants. In the future, this would mean that smaller buffers and thinner walls for plant components would suffice, which would reduce material costs.

The team had already presented a flexibly operable reactor type in an earlier study. The next step will now follow at the Jülich Research Centre: pilot plants that demonstrate the new pressure control and high load dynamics under realistic conditions.

The difference: conventional ammonia synthesis requires a minimum load of 50 percent for operation. According to a study from 2020, load changes of 0.3 percent per minute are possible. The novel plant shown in a simulation can operate at only ten percent load and is therefore better suited to fluctuating green electricity. It can increase or decrease its load by 3 per cent within a minute. It takes 16.36 minutes to ramp up from 50 to 100 per cent load. Conventional ammonia synthesis, on the other hand, requires two and a half hours. Photo: Adobe Stock/Graphic: Forschungszentrum/Reisen