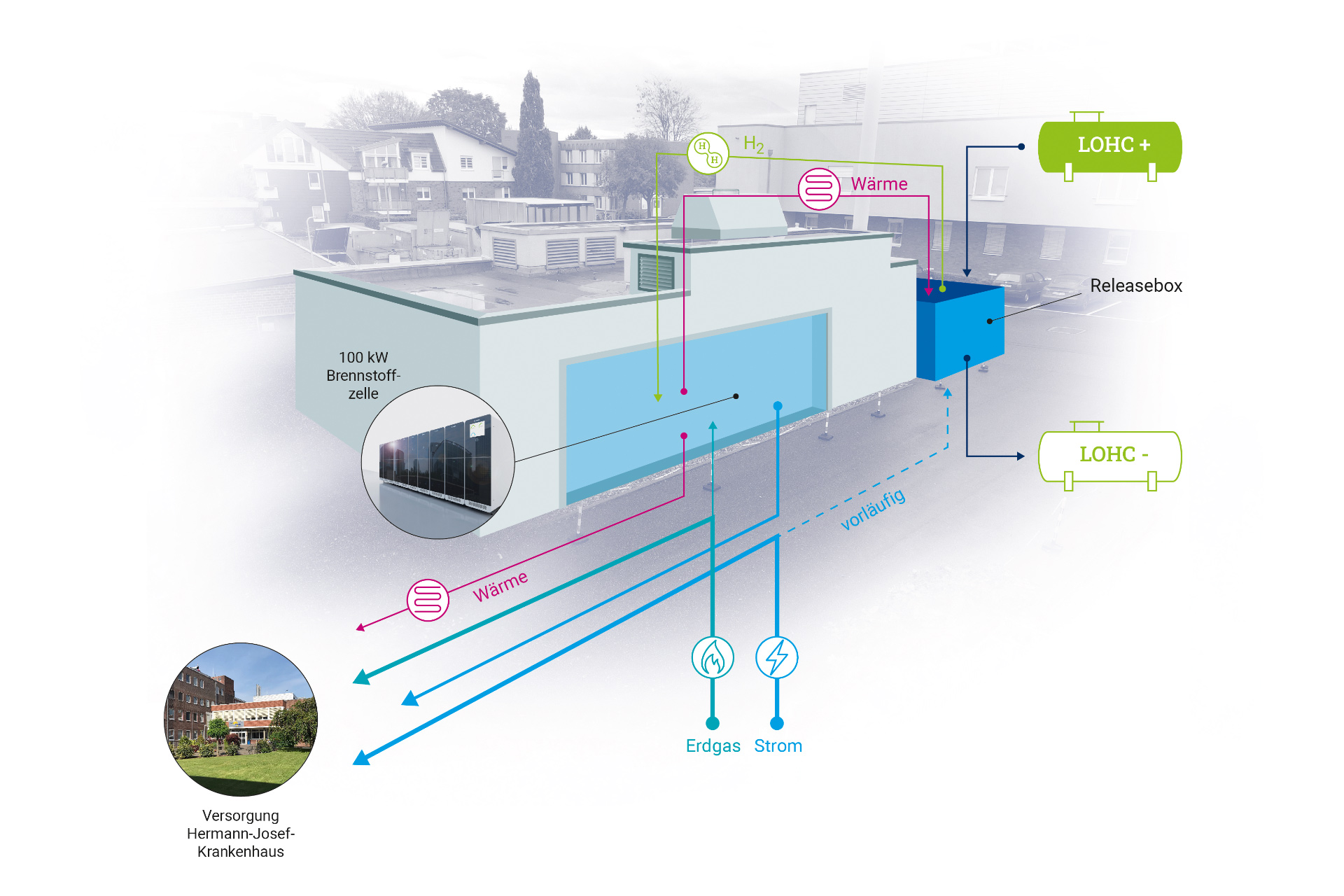

Jülich/Erkelenz. The Hermann-Josef-Krankenhaus (HJK) hospital in Erkelenz is becoming a pioneering project for the environmentally friendly energy supply of the future. At the hospital, Robert Bosch GmbH and Hydrogenious LOHC NRW GmbH are demonstrating the coupling of new hydrogen technologies on an economically relevant scale for the first time. The project is contributing to the energy transition and is one of the major projects in the Rhenish mining area whose research findings will contribute to the success of structural change. The Helmholtz hydrogen cluster (HC-H2), which was initiated and is sustainably supported by Forschungszentrum Jülich, coordinates the demonstration project.

The objectives of the Multi-SOFC project are to significantly reduce CO2 emissions and achieve a more efficient energy supply at the hospital. The partners want to demonstrate the innovative combination of two novel hydrogen technologies by the end of 2026 and with this, to evaluate a more environmentally friendly and more cost-effective solution in the long term. The aim is to assess whether half of the hospital’s base load can be covered by the Multi-SOFC project. The demonstration project is intended to serve as a globally visible model for the future energy supply of large buildings. The German Federal Ministry of Education and Research is providing the Multi-SOFC project with € 23.6 million in funding.

The focus is on a solid oxide fuel cell (SOFC) system produced by Robert Bosch GmbH to supply electricity and heat. In a later expansion stage beginning in early 2025, the SOFC will be supplied with hydrogen based on liquid organic hydrogen carrier (LOHC) technology provided by Hydrogenious LOHC NRW GmbH, a subsidiary of Hydrogenious LOHC Technologies in Erlangen.

You can find out more about the LOHC technology in the supplementary information below.